Information: med reference til F‐gas regulativet EU No. 517/2014, har CTS siden 1. april 2017 skiftet fra kølemidlet R404A til det nye og mere miljøvenlige kølemiddel R452A. Dette bliver et krav fra 2020 men CTS har valgt at tage dette skridt allerede nu. Skiftet af kølemiddel har ikke nogen praktisk betydning på langt de fleste produkter,

bort set fra at alle skabe med ”single stage-kølesystem” vil have en absolut laveste temperatur på -40°C uanset hvad der ellers står i databladet.

Der er naturligvis en længere forklaring og til de interesseret kan den officielle tekniske udmelding fra CTS GmbH læses herunder.

Information regarding the F‐gas regulation (EU No. 517/2014)

The F‐gas regulation is effective since 1 January 2015. The scope of this regulation is to reduce the emission of fluorinated greenhouse gases. This regulation is valid for the operators of the following equipment:

- stationary refrigeration equipment

- stationary air‐conditioning equipment

- stationary heat pumps

- refrigeration units of refrigerated trucks and trailers

In the following, we have summarized the most important contents. The information corresponds to the current state of knowledge (Nov. 2014) and is valid without engagement. Changes may be made at interim by the legislator.

Article 3: Prevention of emissions of fluorinated greenhouse gases

(2) Operators of equipment that contains fluorinated greenhouse gases shall take precautions to prevent the unintentional release (‘leakage’) of those gases. They shall take all measures which are technically and economically feasible to minimise leakages.

(3) Where a leakage is detected in such equipment, the operators shall ensure that this equipment is repaired without delay. Where a leak in the equipment has been repaired, the operators shall ensure that the equipment is checked by a certified natural person within one month after the repair to verify that the repair has been effective.

(4) Companies doing the installation, servicing, maintenance, repair or decommissioning of such equipment shall be certified and shall take precautionary measures to prevent leakage of fluorinated greenhouse gases.

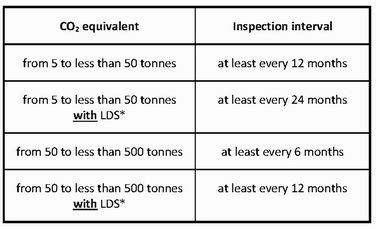

Article 4: Leak checks

(1) Operators of equipment that contains fluorinated greenhouse gases in quantities of 5 tonnes of CO2 equivalent or more which are not contained in foams shall ensure that the equipment is checked for leaks. Exception till 31 December 2016: Equipment that contains less than 3 kg of fluorinated gases (or 6 kg when hermetically closed) is not subject to control. From 1 January 2017 the new CO2 equivalents are also valid for this equipment.

LDS* → leakage detection system according to Art.5

Article 5: Leakage detection systems

(1) Operators of equipment that contains fluorinated greenhouse gases in quantities of 500 tonnes of CO2 equivalent or more shall ensure that the equipment is provided with a leakage detection system which alerts the operator in case of a leakage.

(3) Operators shall ensure that the leakage detection system is checked at least once every 12 months to ensure its correct functioning.

Article 6: Record keeping

(1) Operators of equipment which is required to be checked for leaks according to Article 4(1) shall establish and maintain records for each piece of such equipment specifying the following information:

a) the quantity and type of fluorinated greenhouse gases installed

b) the quantities of fluorinated greenhouse gases added during installation, maintenance or servicing or due to leakage

c) whether the quantities of installed fluorinated greenhouse gases have been recycled or reclaimed, including the name and address of the recycling or reclamation facility and, where applicable, the certificate number

d) the quantity of fluorinated greenhouse gases recovered

e) the identity of the company which installed, serviced, maintained and, where applicable, repaired or decommissioned the equipment, including, where applicable, the number of its certificate

f) the dates and results of the checks done according to Article 4(1) to (3)

g) if the equipment was decommissioned, the measures taken to recover and dispose of the fluorinated greenhouse gases.

The operator must keep these records for at least five years. Companies doing the activities for operators shall keep copies of the records for at least five years.

Article 8: Recovery

(1) Operators of stationary equipment or of refrigeration units of refrigerated trucks and trailers that contain fluorinated greenhouse gases, not contained in foams, shall ensure that the recovery of those gases is done by persons or companies with relevant certificates according to Article 10, so that those gases are recycled, reclaimed or destroyed.

Article 10: Training and certification

Until 1 January 2017, Member States shall establish training and certification programmes, including evaluation processes, for the following persons:

- Persons which install, service, maintain, repair or decommission the equipment

- Persons which carry out leak checks

- Persons which recover fluorinated greenhouse gases

Article 13: Control of use

(1) Up to the 31.12.2019, there is no restriction.

(2) From 01.01.2020, the use of fluorinated greenhouse gases in new equipment, with a global warming potential (GWP) of 2 500 or more shall be prohibited. This paragraph shall not apply to equipment intended for cooling products below – 50 °C, where normally R23 is used. Also this refrigerant has a GWP of 14.800, it is still allowed.Existing equipment can still be used till 31.12.2029; also the refrigerant has a higher GWP. Only service or maintain refrigeration equipment with a charge size of 40 tonnes of CO2 equivalent or more (≥ 10.2 kg R404A) shall be prohibited and must be filled in with recycled refrigeration. Alternatively in such a case, the equipment could be filled with other refrigerants like R452A.Below a charge size of 40 tonnes of CO2 equivalent, means below 10,2 kg R404A, the equipment could be refilled with new R404A in service cases till 31.12.2029

(3) From the 01.01.2030, you have to use also in Service refrigerant with GWP ≤ 2500.

Realization of Article 4 (leak check) on the basis of an example:

Climatic test cabinet type C‐70/600 For the quantity and type of the refrigerants as well as the CO2 equivalent see type plate (from 1 January 2015).

- R404A: 2,3 kg x 3922 (GWP value) →9020.6 kg →9,02 tonnes (CO2 equivalent)

- R23: 0,84 kg x 14800 (GWP value) →12432 kg →12,43 tonnes (CO2 equivalent)

The higher CO2 equivalent value prevails, i.e. in the example 12,43 tonnes. This results in a control interval of at least every 12 months or, with a leakage detection system, every 24 months (see chart of Article 4).

Statement on the status of the refrigerating agents used at CTS regarding the F‐gas Regulation (version: 24/2/2017)

(1) At the moment, R23 is the only non‐flammable refrigerating agent available in the deep‐cooling stage for all devices with a temperature range <‐40°C. The F‐gas Regulation therefore places no restrictions on its use.

(2) At the pre‐deep‐cooling stage of cascade units, for these devices and single stage devices with a temperature range ≥‐40°C, R404A can be substituted by alternative agents available on the refrigerating agent market. Compared to R404A, some of these have significant thermodynamic and energetic disadvantages when operating refrigerators.

(3) For some time, various devices have been run with these alternatives at CTS and we have come to the following conclusion:

- R449A: it is true that this refrigerating agent has a low GWP but, thermodynamically, it is far from being the best alternative, because the compressors have a much higher stress, among other things.

- R452A: according to our examination, this refrigerating agent is, at the moment, the best alternative for R404A, especially in relation to the compressor’s lifetime

(4) CTS devices with a year of construction as from approx. 2008 can be converted to use an alternative refrigerating agent in the pre‐deep‐cooling stage or in the case of single‐stage loops, with a relatively low level of investment (Drop‐In Solution)

(5) R452A: more details:

- All incoming orders from 01. April 2017 are supplied and filled from CTS with the new refrigerating agent (R452A instead of R404A) Note in the order confirmation: In line with the specifications set out in the F‐gas Regulation, the refrigerating agent R404A is substituted by R452A.

- R452A has a GWP of 2141 and therefore below the GWP limit of 2500

- The refrigerating agent R452A is more expensive than R404A (at CTS it costs the same as R404A)

- All single‐stage standard devices (C and T series, not stress) remain below the limits of the CO2 equivalent of 5 tonnes determined in the F‐gas Regulation and are thus NOT subject to a leak test

- Final value ‐40°C (single stage cabinets)

(6) On special customer request and after consulting CTS it is possible in principle to use R449A (restricted performance specifications possible).